Phencore ™

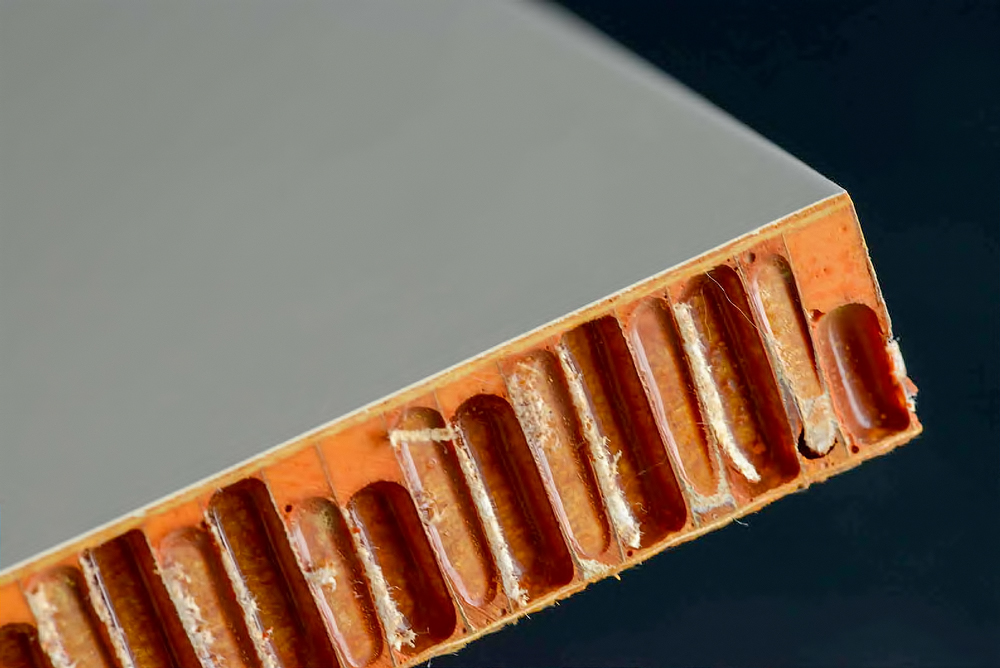

Phencore™ is an advanced sandwich composite invented and trademarked by BFG International. Taking the form of a robust phenolic skinned panel with a honeycomb Nomex core, Phencore™ delivers high levels of flame resistance – and significant weight benefits – in a flexible, customisable form.

Developed and patented by BFG, and launched in 2013 as an alternative to traditional aluminium honeycomb panels, Phencore™ offers excellent strength and fire performance across a diverse range of commercial, transport and architectural applications. Its strength-to-weight characteristics are impressive - weighing up to 70% less than the equivalent aluminium honeycomb. Phencore™ panels can be delivered in a painted or glossy High Pressure Laminate (HPL) finish.

Phencore™ panel design and construction

Phencore™ panels typically feature phenolic composite skins laminated and bonded to an aramid honeycomb core. Individual layers are bonded using a proprietary processing technique. The cell size in a standard Nomex honeycomb is just 5mm, against a standard 12mm cell size in aluminium honeycomb panels. Phencore™’s lower cell size increases the contact area for bonding and provides better load transfer.

The phenolic resin adds high fire resistant performance and low smoke and toxicity benefits. The aramid honeycomb imparts excellent crush strength, stiffness and structural integrity.

Characteristics

- Extremely lightweight

- Excellent stiffness

- High strength to weight ratio

- Excellent fire resistance – meeting standards in the UK, France, Germany, USA, Russia and beyond

- High temperature resistance

- Corrosion resistant

- Excellent dielectric properties

- Thermally insulating

- Good thermal stability

- Good acoustic performance

- Easy to repair using standard FRP repair techniques

- Can be formed to complex acute and oblique curves as well as flat geometry

Customisation

Phencore™ has fully flexible design architecture, with customisable properties for high-end use. Each panel can be tailored to fit a whole range of specific applications including:

- Moulding from flat to three dimensional curved geometries

- Assembly using standard techniques or customised to suit assembly interfaces

- Availability in a range of thicknesses

- Painting with gloss, matt, textured or decorative finishes using HPL.

Applications

- Automotive, rail, aviation and construction

- Floor panels

- Interior panels

- External panels

- Ceilings

- Side linings

| Fire Performance | |||||

|---|---|---|---|---|---|

| United Kingdom BS 6853 |

France NFF 16101 |

Germany DIN 5510 |

United States NFPA 130 |

Europe EN 45545 (R1 for interior R6 for exterior) |

Russia GOST (30402-96 & 12.1.044) |

| Category 1a for interior scope | M1 F1 | S4/SR2/ST2; FED( 30 min ) = 0.07 |

FSI = 5; Ds (1.5 ) = 14; Ds (4 )= 47; |

HL2 | B1 D1 T1 |

| Category 1a for interior scope | M1 F1 | S4/SR2/ST2; FED( 30 min ) < 1 |

FSI < 15; Ds (1.5 ) < 100; Ds (4) < 200 |

HL2 | B1 D1 T1 |